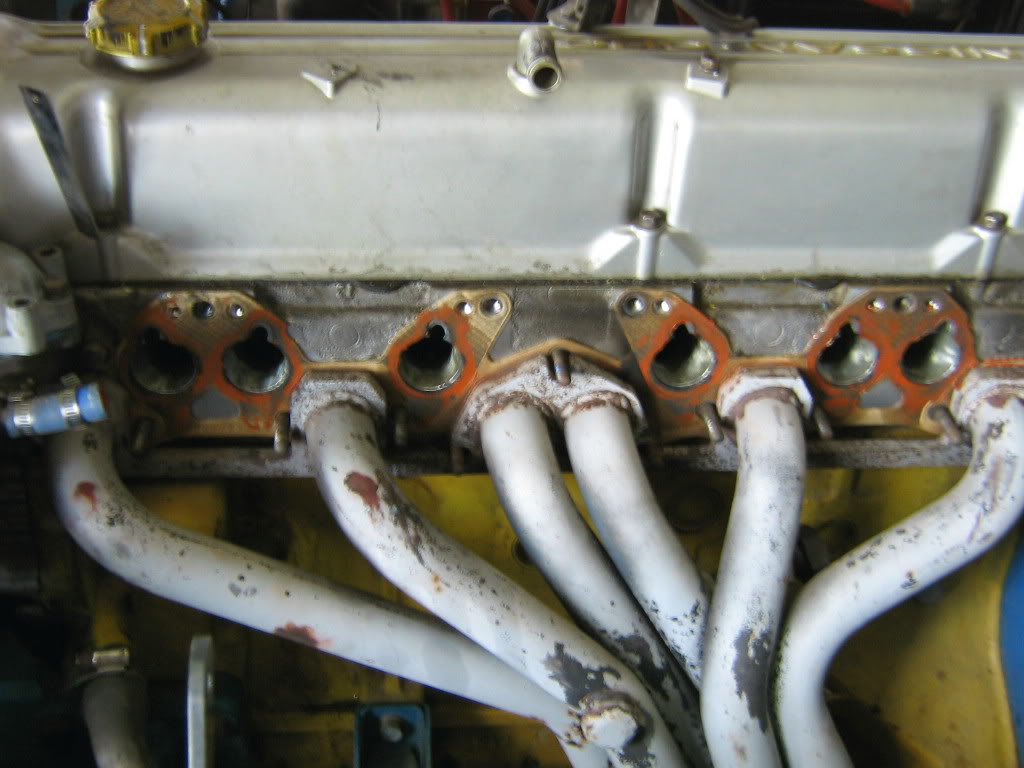

Gasket goop.

#1

Gasket goop.

I'm pretty sure I'm prepared to replace my leaky header now.

I've never had to do this before though, so just one question: Is there some kind of "goop" or something that you're supposed to wipe on the gasket?

I got one from MSA. None of the tutorials I've read say to use a sealant of any kind on the gasket... what should I use?? how should it be applied??

Shady280, if you read this, your walkthrough was good, but this piece of information would make it better.

and how should I treat the face of the header that would be touching the gasket? should it get painted with engine enamel like the rest of the header, or should I go out of my way to keep it bare metal?

Thanks

I've never had to do this before though, so just one question: Is there some kind of "goop" or something that you're supposed to wipe on the gasket?

I got one from MSA. None of the tutorials I've read say to use a sealant of any kind on the gasket... what should I use?? how should it be applied??

Shady280, if you read this, your walkthrough was good, but this piece of information would make it better.

and how should I treat the face of the header that would be touching the gasket? should it get painted with engine enamel like the rest of the header, or should I go out of my way to keep it bare metal?

Thanks

#4

-Andrew

#6

#8

Should be OK

Alternators are subject to moisture, rain etc, washing the engine, gets them wet, the wires inside have a plastic insulation on them, so it shouldn't be a problem. It probably wouldn't run submersed in liquid, but a little spillage should run right through.

#9

+1 - good stuff. They have a good high temp anti sieze as well. Just be careful with anti sieze that they are the correct metal x to metal x or y combination.

#10

there's no sense in using rtv on the intake side, its absolutely pointless. You can either use coppercoat, which I would highly recommend. Or if you just have to use RTV, you can buy high temp rtv silicone that is orange in color, it will withstand the temperatures at the head/manifold area. But you're only masking a problem rather than fixing it for good. You need to check for head warpage and manifold warpage. And make sure all your studs are there. Convert to studs all the way around instead of bolts, and buy new washers from MSA. If #1 and #6 studs are broken, drill them out to accept 10mm studs.

#11

yeah that coppercoat is all you need if your worried. lately i havent even had to use it after ive had the header flange straightened or know its perfectly flat. if unsure or want extra insurance then coppercoat is awesome stuff. thats kinda a personal preference.

Thread

Thread Starter

Forum

Replies

Last Post

Warpix

240Z, 260Z, 280Z Performance / Technical

6

06-11-2009 09:19 PM

Bookmarks