Valve adjusting suggestions anyone?

#1

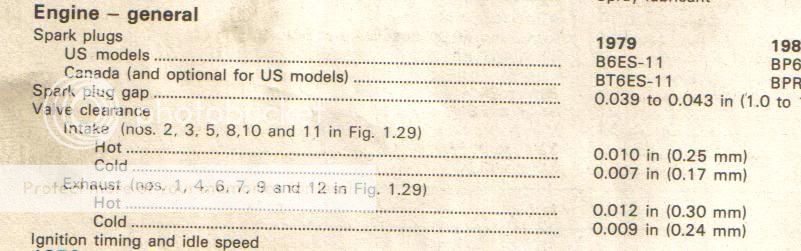

My buddy helped me a while back to adjust my valves, I had to call him on the phone and he thumbed through his Chilton and told me the settings. The thumbnail is what he said the book said to do. I am going to re-adjust my valves tomorrow and I wanted to know if I should adjust them to different specs than what I was told. I am not sure if the specs he sent me were for a "fresh valvetrain" as mine is not with 93,XXX miles on the original stuff. What would you all do? They have started ticking again since my overheating thing happend. I would like to quiet them up for a while but I cannot get new parts yet, so these will have to last a bit longer. Thanks guys.

Attachment 4768

Attachment 4768

Last edited by thxone; 02-27-2007 at 03:01 PM.

#2

those specs he gave you are the Nissan recommended specs. The tighter clearance is the intake valves, while the wider is the exhaust valves. The intake valves very rarely need to be adjusted however. It's usually just the exhaust valves that are out of whack. But check them all just to be safe.

#3

Also what the Z guru here told me is they need to be adjusted every 15k miles or so. Because mainly we don't have lifters on our L28's. Sometime soon, I want to get mine adjusted. I haven't adjusted mine since '02, when I had my head replaced on my '81 motor. Which is in my '82 now.

#5

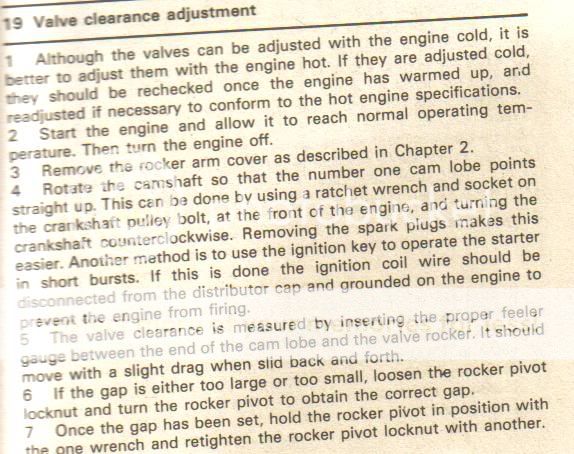

So then I should not adjust them to a different spec then to compensate for wear? And for clarification I used the feeler gauges that look like flat slivers of metal---> when I use these, should I be able to move them freely or should they be tight between cam lobe and the arm or should they move but with resistance?

#7

Acording to that, I did it correctly when I adjusted them the first time...so it should be old hat this time...you guys rock, and hey check it out, my post are over 200. I feel special.

Last edited by thxone; 06-04-2006 at 10:44 PM.

#8

Originally Posted by thxone

So then I should not adjust them to a different spec then to compensate for wear?

Originally Posted by thxone

And for clarification I used the feeler gauges that look like flat slivers of metal---> when I use these, should I be able to move them freely or should they be tight between cam lobe and the arm or should they move but with resistance?

#9

That sounds cool to me, but when I did this before, its almost like you need a third hand because I would check with the gauge after tightening the nut ( the one that locks it all into place) and I couldn't get the gauge back in...I may try a slightly different approach tomorrow.

#10

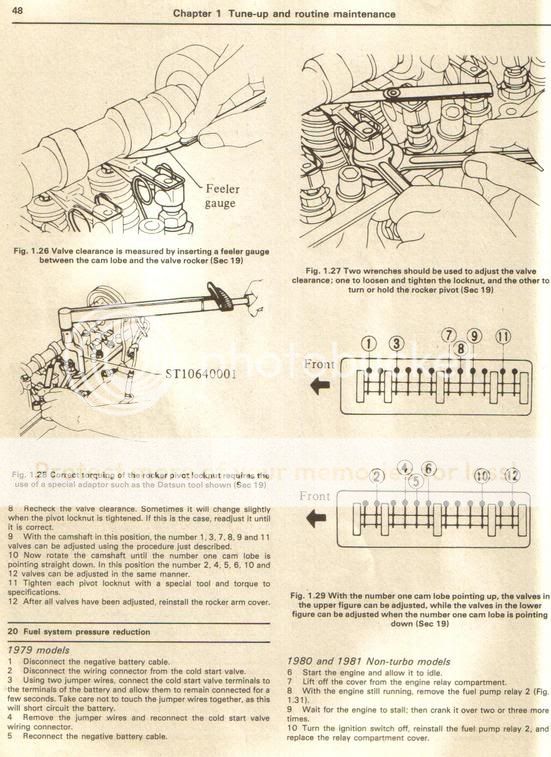

One more question...after reading your pics NismaoPick it says to adjust the first set with the #1 lobe in the up position. Do I adjust 1 3 7 8 9 and 11 with the #1 lobe up or do I have to adjust #1 then turn the crank till #3 is up and adjust it and so on? Because thats what I did and if I read that correctly it say adjust them all with just #1 pointing up then when its down do the others...Help me O wise one.

#11

When I do it... I just go through & adjust all the ones that the cam lobe is facing more or less up. The lobe part of the cam just needs to be NOT touching the rocker at all. But when ya need... just flick the key real quick to move it.... or have a rachet on the crank to manually move it to the desired position.

#14

dont forget to do the adjustments when the car is warm, it makes for a better adjust, i get someone to keep moving the feeler when im tightening so that it is perfect, its harder alone, but not too bad

#16

Originally Posted by PooFlinginMonke

Funny thing is that many will actually get a closer tolerance as the valve sinks into the seat from mileage.

#17

on my P79 my exhaust tolerances would get tighter whereas the intake valves would have excessive clearance. I can't say whether its from valve sinkage or not though. My P90 is hydraulic so I dont have to worry about any of that for now.

#19

Registered User

Joined: Jul 2003

Posts: 532

From: Houston Tx. Cleveland Tx. New Caney Tx. and every other Tx.

Well yea the 76 heads have hard seats. but if you have had machine work like I have 3 angle grinde well I am woundering how that is going to afect how often I have to adjust mine. all my valve train parts including springs are all bran spanking new.

#20

with new stuff, i have found that you must adjust about every 2 weeks or so untill the parts wear in. the frequency lessend as time goes by, new rockers essecially need more attension then any other type of part swap.

#21

yeah the parts need a chance to develop their wear patterns onto each other. Once that happens the amount of wear each part endures becomes minimal compared to a new part because the parts actually fit together at that point.

#22

Registered User

Joined: Jul 2003

Posts: 532

From: Houston Tx. Cleveland Tx. New Caney Tx. and every other Tx.

I just have to be carefull with my valve cover gasket taking the cover on and off to adjust. I am cheap, so if I can keep a part in good condition, I will strech it as far as I can.

Thread

Thread Starter

Forum

Replies

Last Post

Bookmarks